FMHero was born out of the real-world challenges faced by HVAC professionals—from endless paperwork and cumbersome recordkeeping to the ever‑increasing complexity of compliance regulations. Designed by experienced HVAC technicians, FMHero bridges the gap between regulatory demands and everyday field operations. With our expertise in full‑cycle app programming, Chop Dawg brought FMHero to life, delivering a mobile app and integrated web‑based admin portal that empower users to document refrigerant management, track service records, and maintain compliance with ease.

Streamline Refrigerant Management and Compliance in the HVAC/R Industry

HVAC/R professionals face daily challenges in maintaining detailed compliance records, managing refrigerant inventories, and ensuring that every service event is accurately documented. Traditional paper‑based systems and outdated digital tools create inefficiencies, increase the risk of fines, and hinder productivity. FMHero was envisioned to solve these issues by offering a digital solution that streamlines record-keeping, reduces administrative burdens, and empowers technicians to work smarter—ensuring that compliance is not just met but exceeded

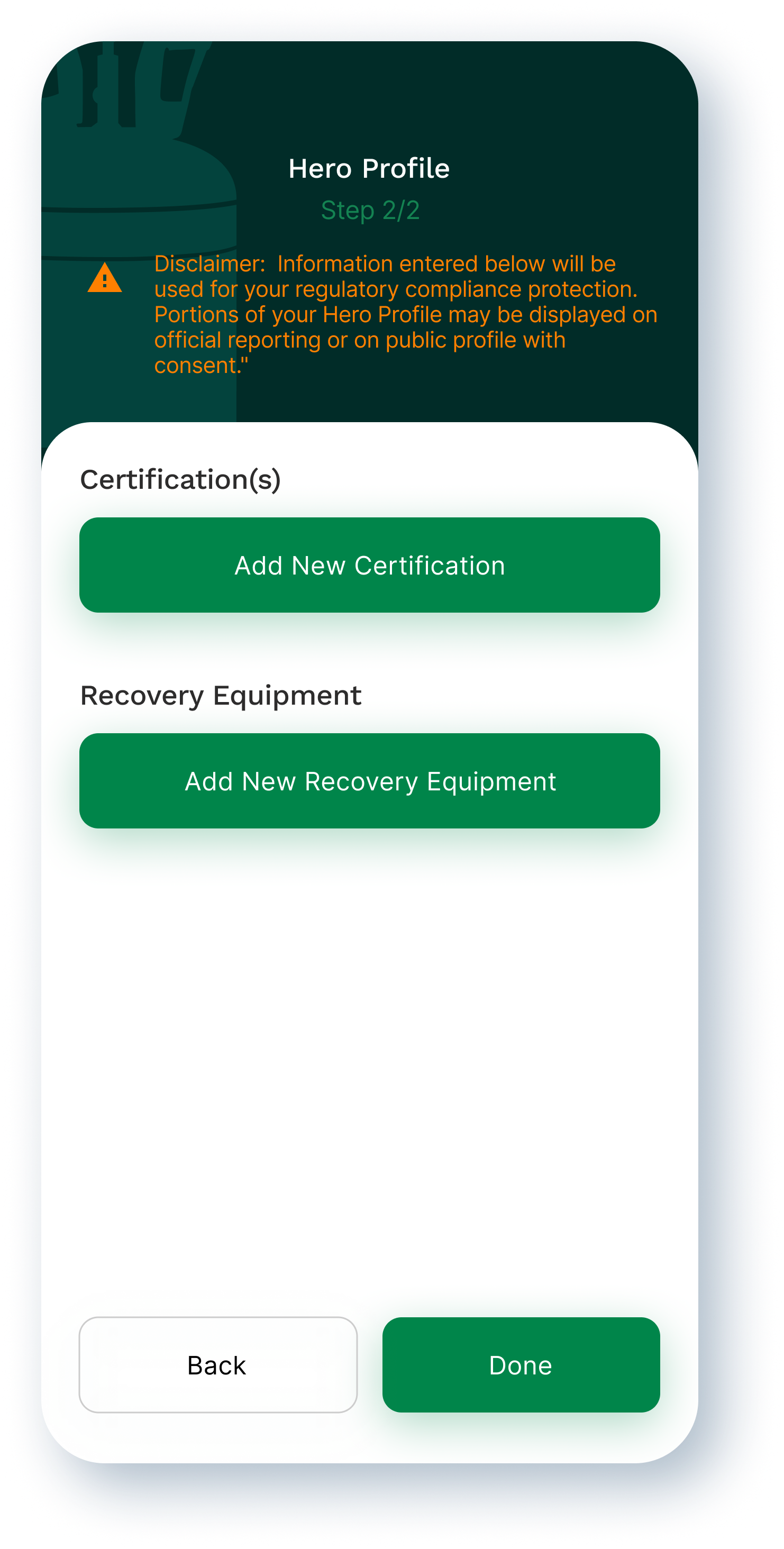

FMHero’s experienced HVAC team provided detailed design assets and functional requirements, and Chop Dawg’s expert programmers took these assets to the next level. By leveraging our agile development process, we built a state‑of‑the‑art mobile app for iPhone and Android and a complementary web‑based admin portal. Through regular Zoom meetings, dedicated Slack channels, and collaborative tools like JIRA, Confluence, GitHub, and Figma, we ensured every feature—from instant unit scanning and location-based data capture to comprehensive cylinder inventory management—was programmed to perfection. Our close collaboration meant that every detail aligned with FMHero’s mission of transforming compliance into a competitive advantage.

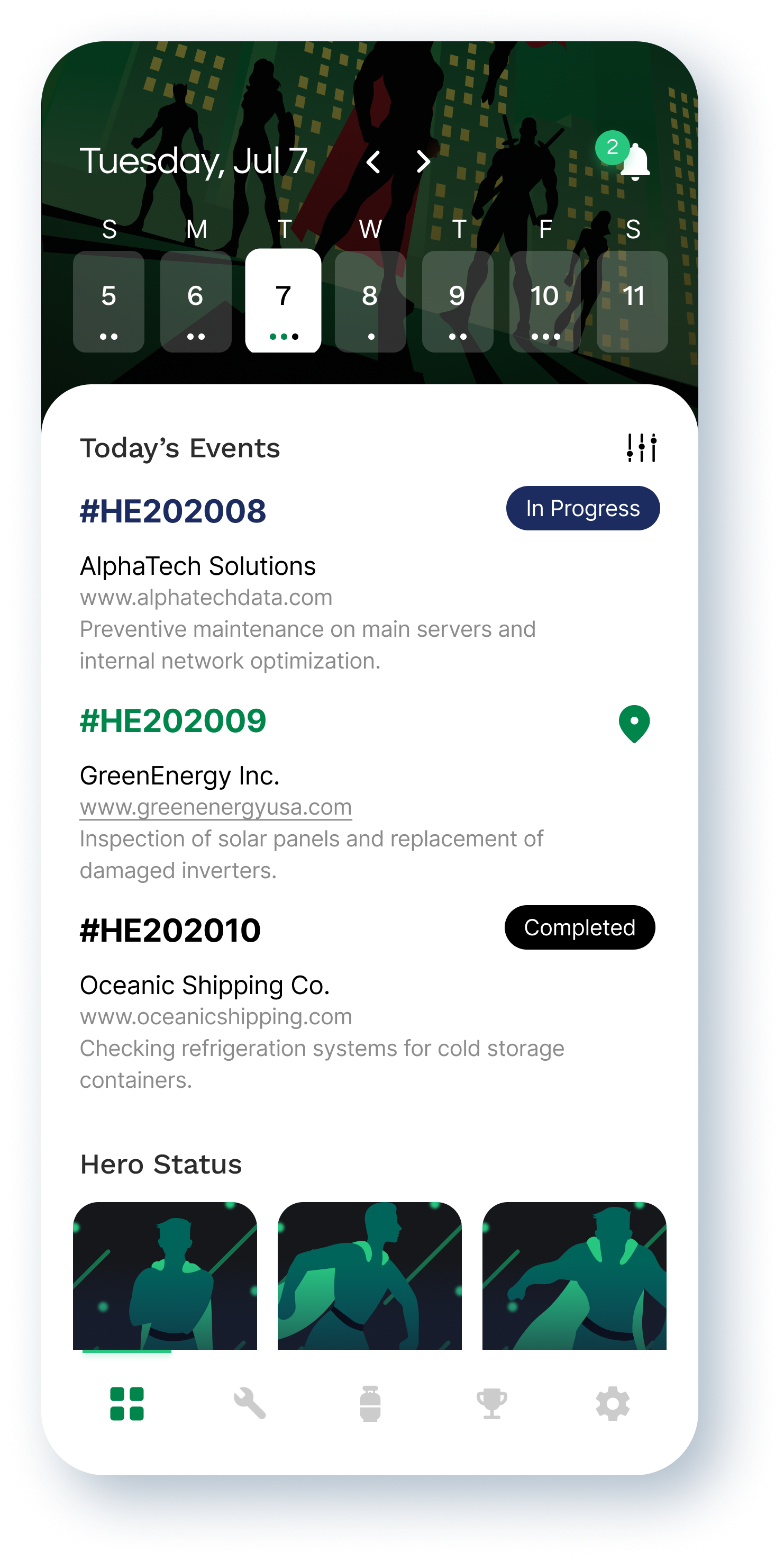

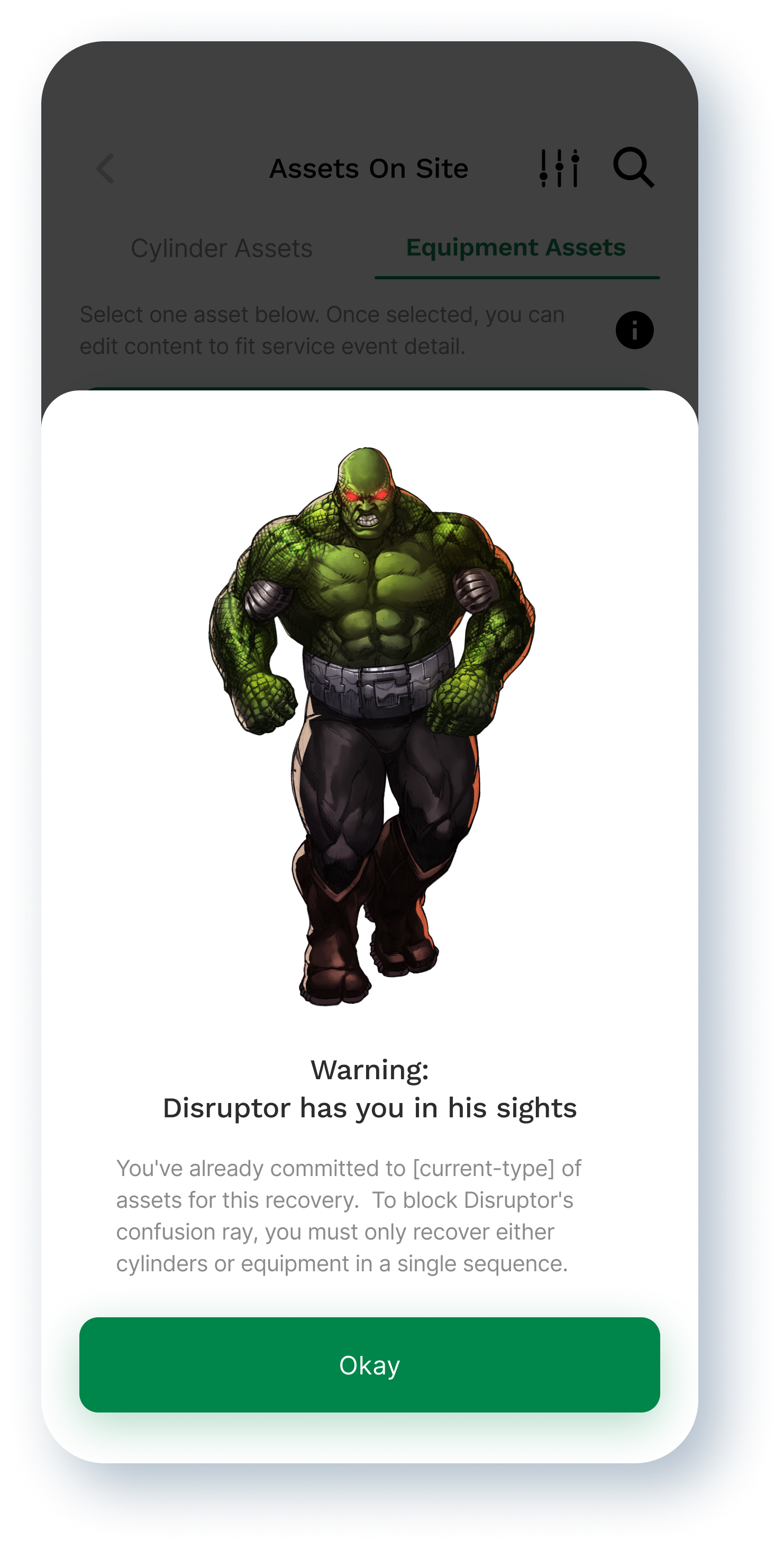

FMHero revolutionizes the HVAC/R workflow with powerful, purpose‑built tools that simplify compliance, enhance documentation, and boost operational efficiency:

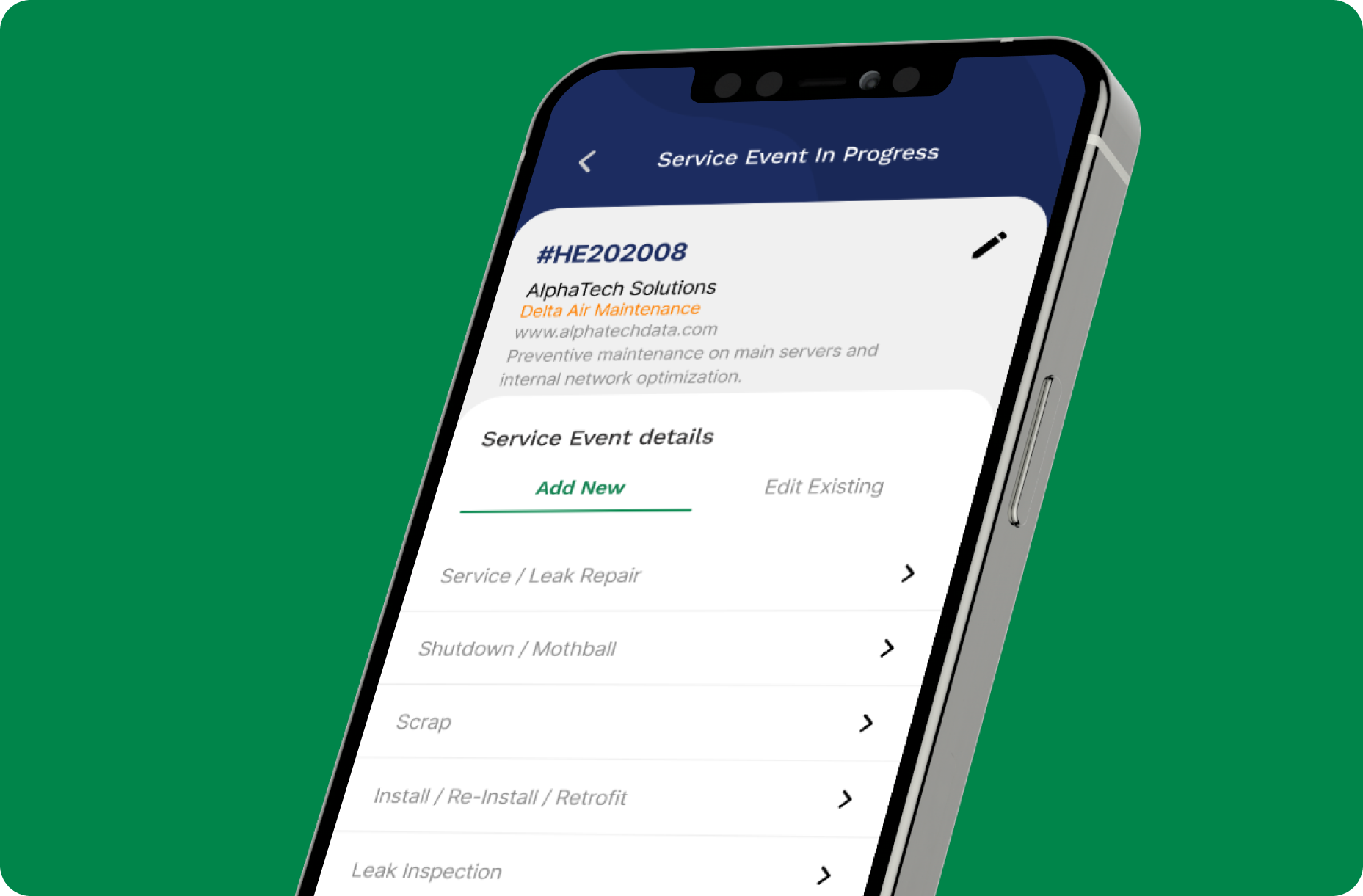

Automated, accurate compliance documentation ensures that every refrigerant service event is recorded in accordance with Section 608 requirements—protecting technicians and their businesses from costly fines.

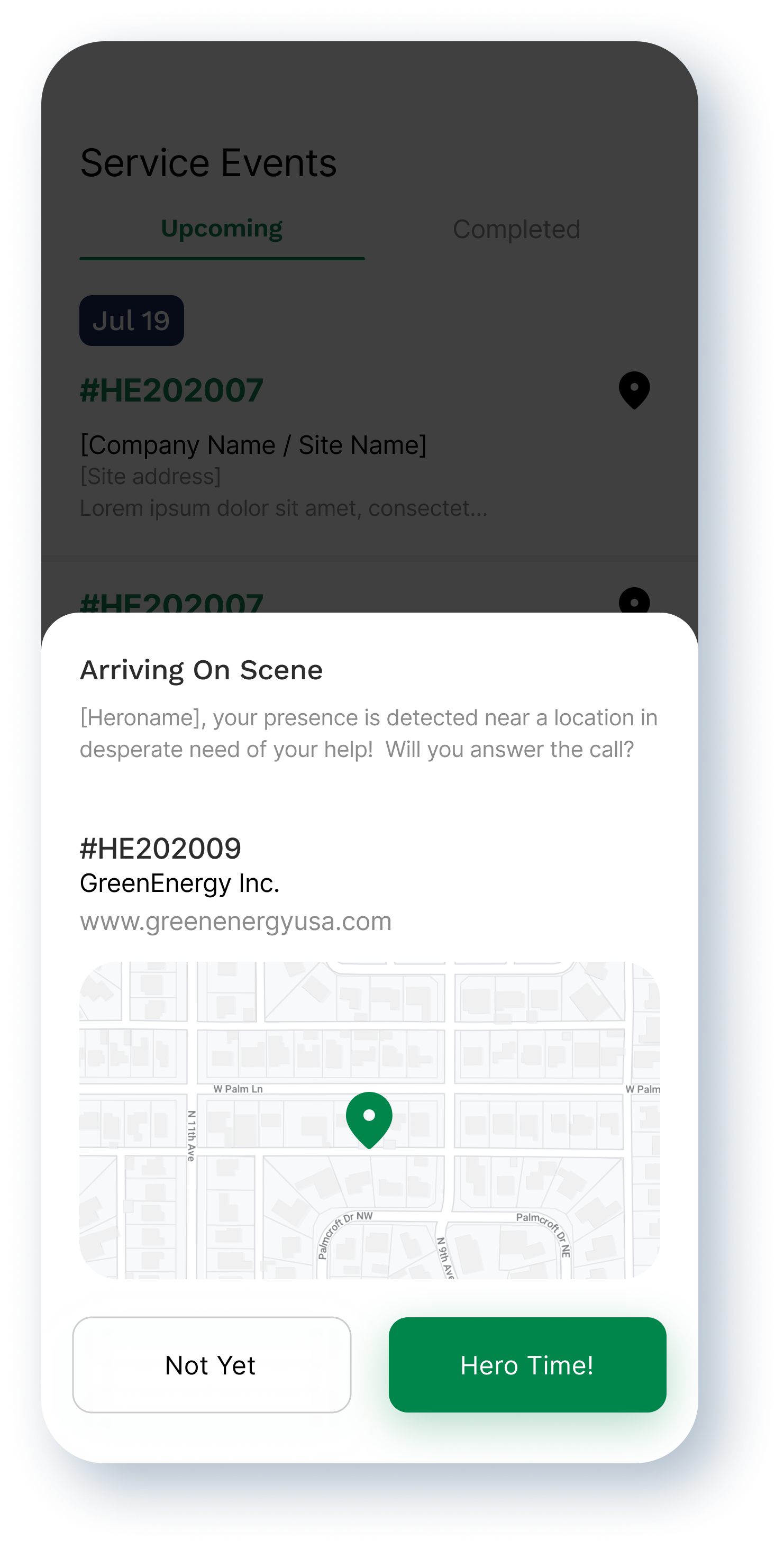

Leveraging mobile device location data, FMHero automatically captures site addresses and relevant details, reducing manual data entry and minimizing errors.

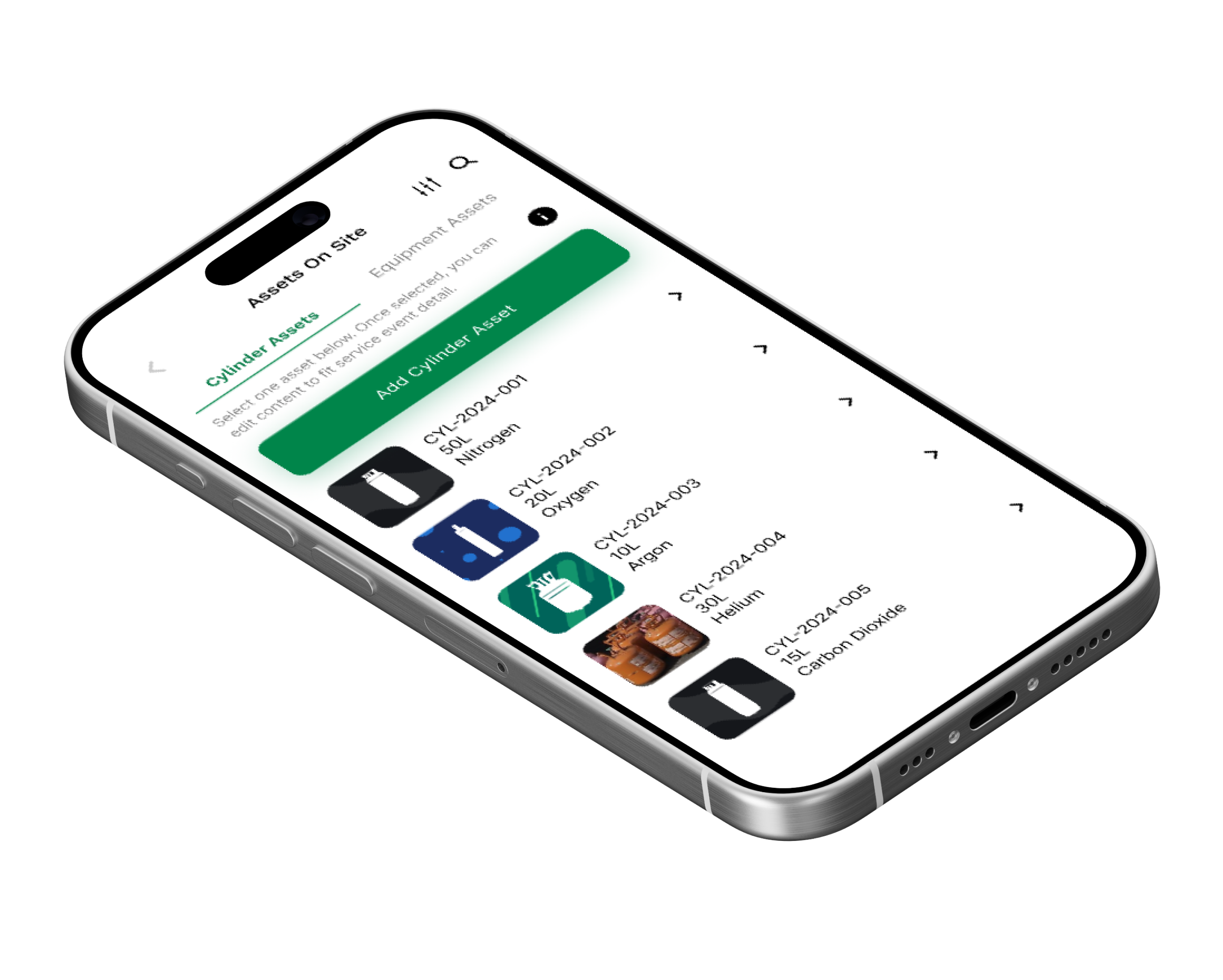

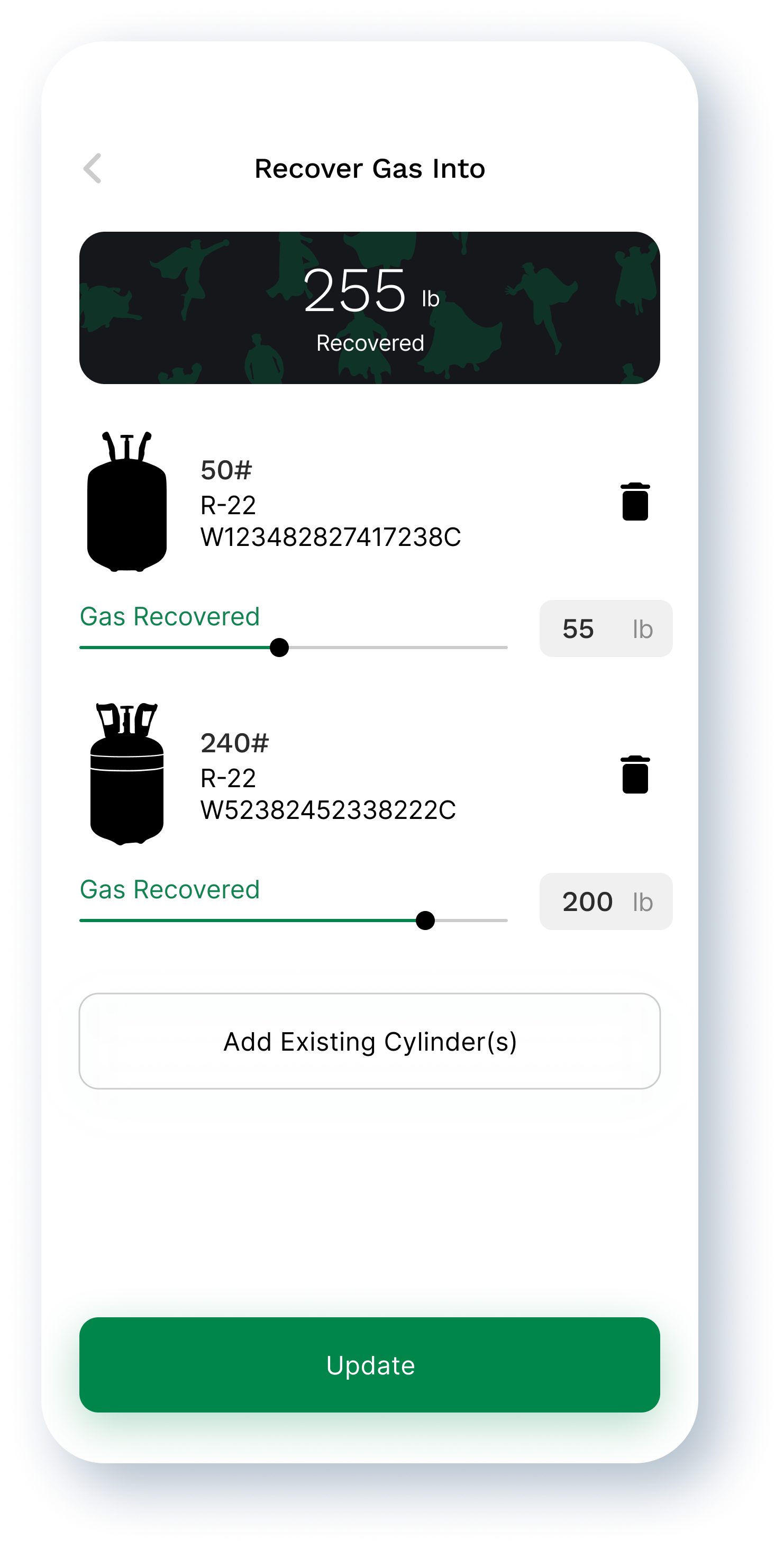

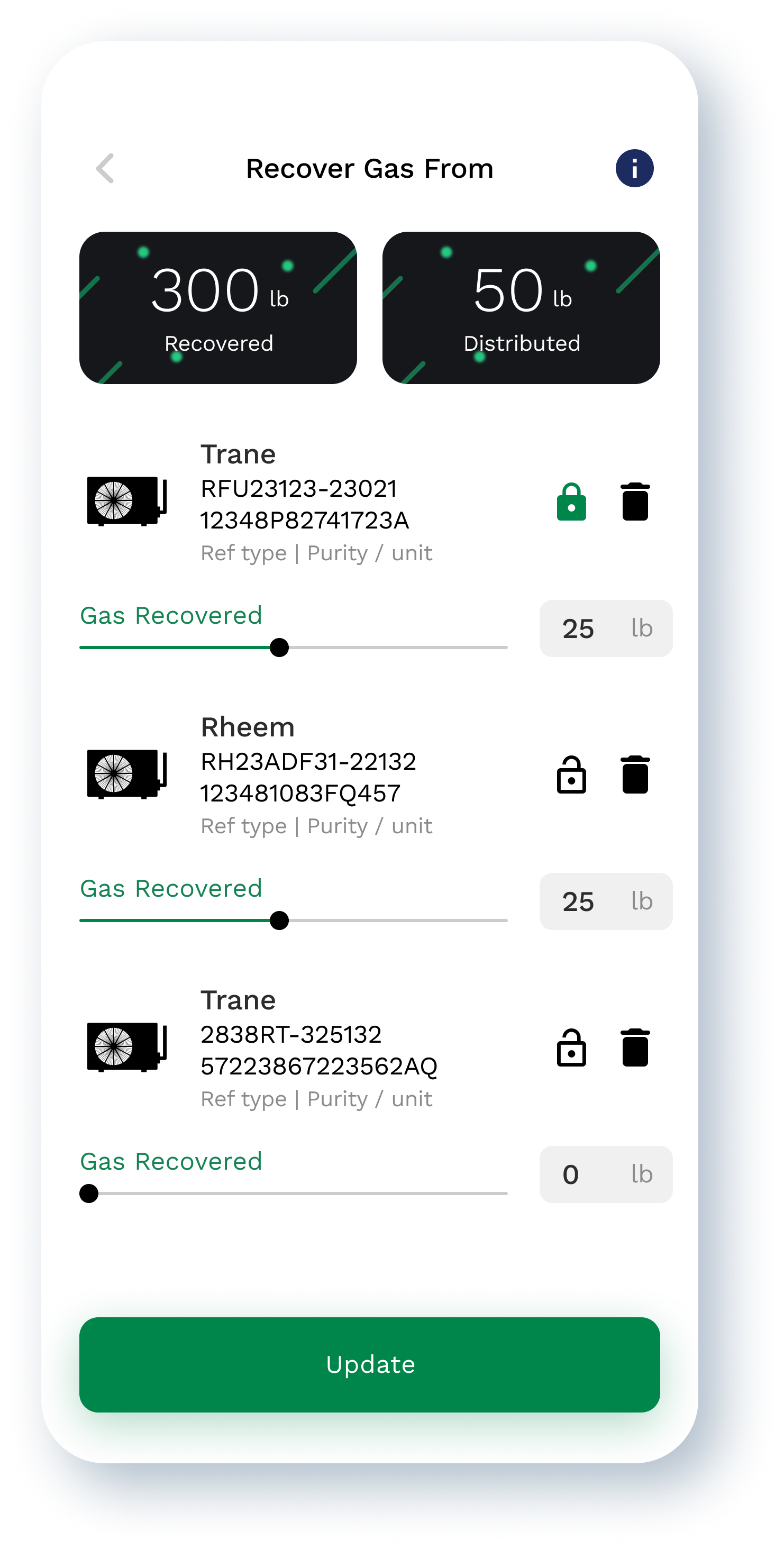

Track all incoming and outgoing cylinders seamlessly. Our intuitive interface lets users manage refrigerant inventories, ensuring a single source of truth for every asset.

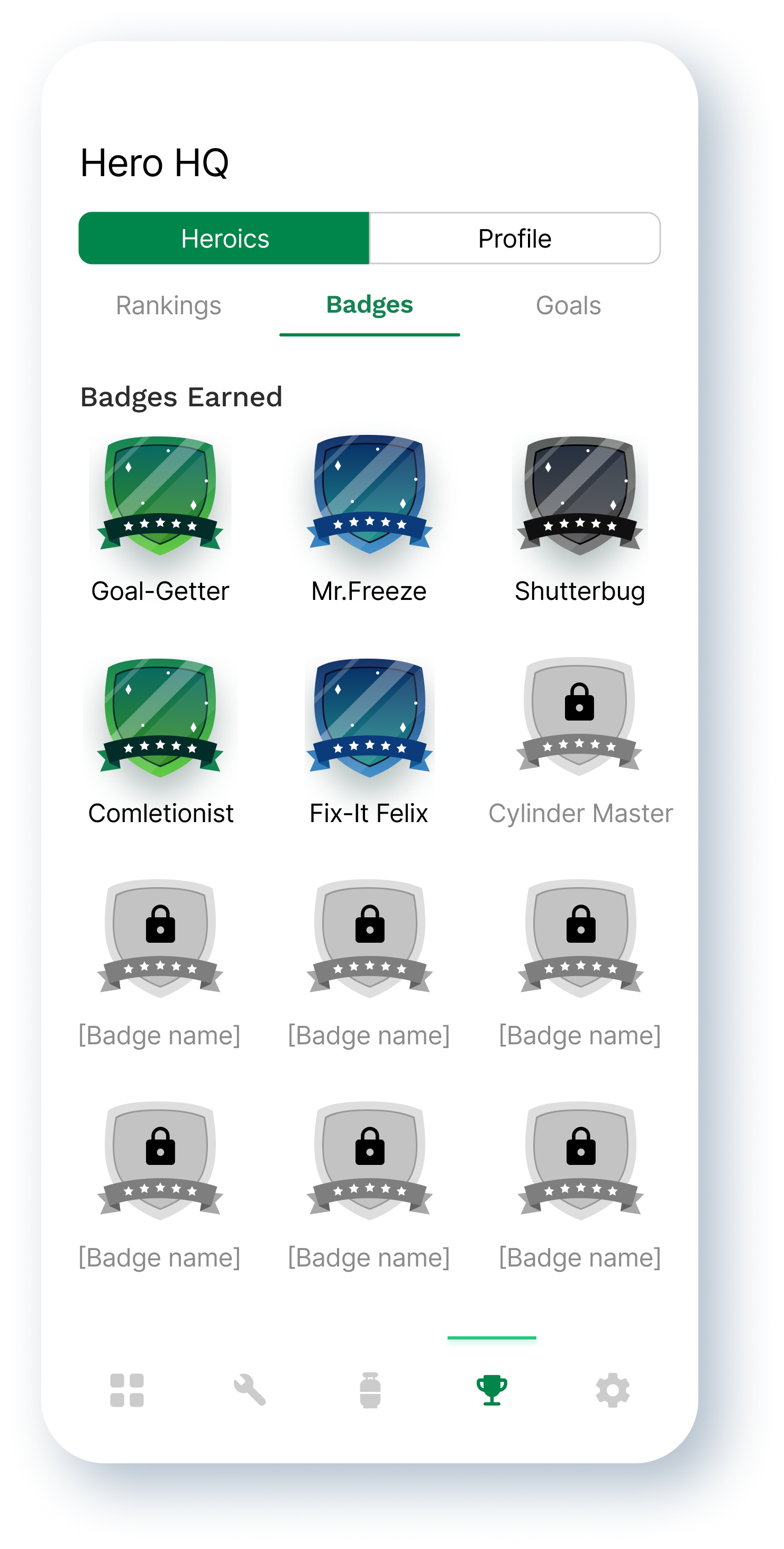

Comprehensive reporting features help monitor technician engagement and track service history—providing insights that drive accountability and improve performance.

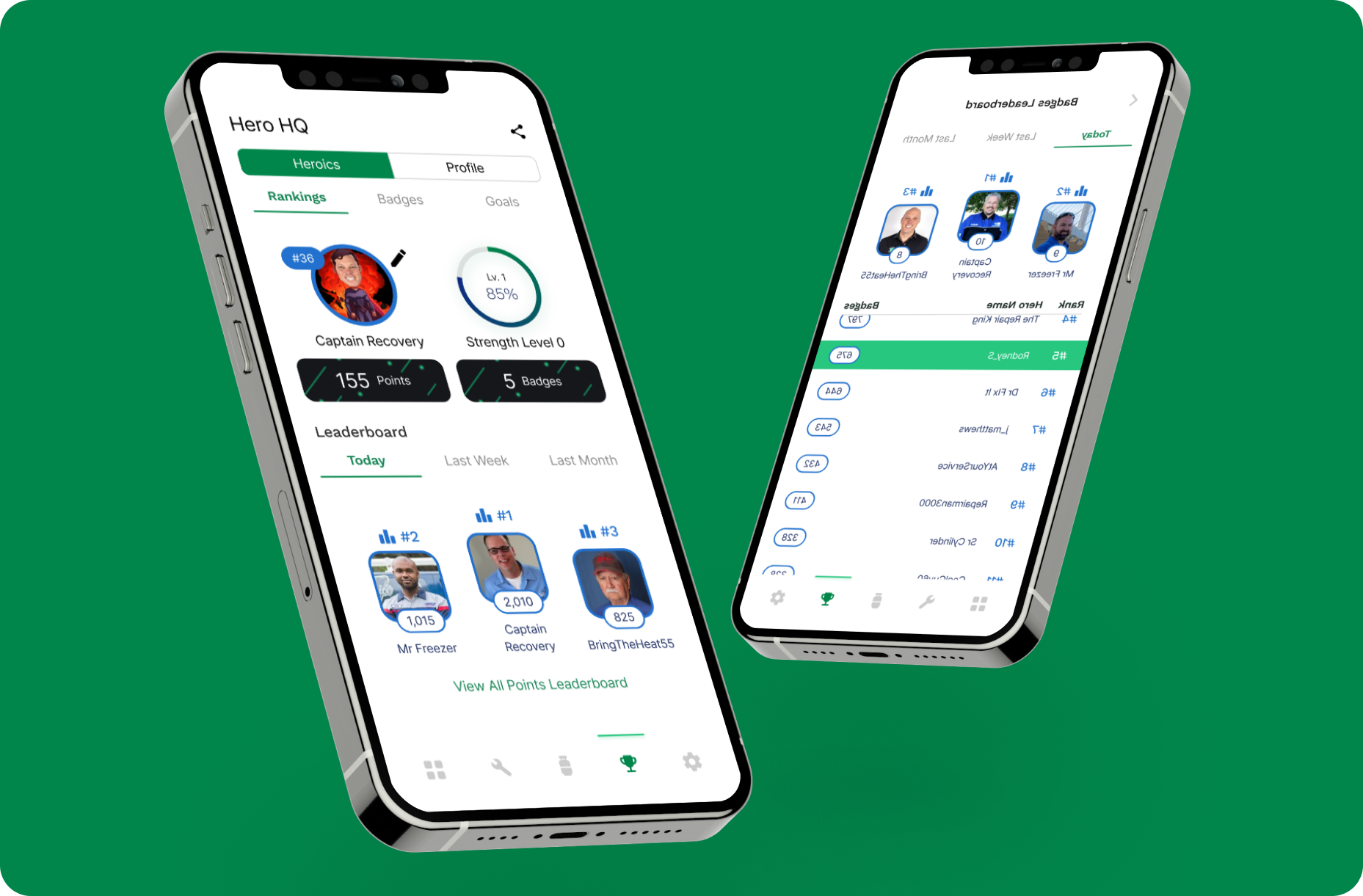

Beyond compliance and documentation, FMHero integrates advanced tools to enhance communication, reporting, and overall field efficiency:

Streamline scheduling and administrative tasks with in‑app appointment setting, freeing technicians to focus on what they do best.

Instantly capture service events, scan unit nameplates, and document refrigerant movements with data-driven insights—ensuring your records are always audit‑ready.

FMHero is designed to comply with EPA Section 608, AIM Act, and ER&R requirements. Our platform ensures that every service, from recovery to leak detection, meets strict regulatory standards.

Chop Dawg’s involvement with FMHero extends far beyond coding. We provided strategic oversight and technical expertise throughout the entire project:

Our programming team transformed FMHero’s in‑house designs into a fully functional mobile and web solution—delivering precision, speed, and reliability on both iOS and Android platforms.

A dedicated QA team conducted extensive testing at every milestone, ensuring that FMHero’s compliance tools, data capture features, and reporting functions met the highest standards.

We provided continuous project management support and established comprehensive documentation, empowering FMHero to manage, scale, and evolve the platform independently after launch.

Throughout the FMHero project, our teams maintained constant, clear communication via weekly Zoom sessions, dedicated Slack channels, and real‑time progress updates through JIRA and Confluence. This agile process allowed us to swiftly integrate feedback—whether fine‑tuning the scanning logic or optimizing the reporting features—resulting in a unified, high‑performance digital solution that truly reflects the needs of HVAC professionals.

Chop Dawg delivered a complete digital ecosystem for FMHero, including a fully programmed mobile app for iPhone and Android and a powerful web‑based administrative portal. Our work encompassed the integration of advanced scanning, data capture, and inventory management features—all based on FMHero’s in‑house designs—ensuring a seamless, efficient experience for HVAC professionals.

FMHero now operates flawlessly on the latest mobile platforms, fully aligned with EPA, AIM, and ER&R compliance standards. Through seamless integration with critical third‑party APIs—such as Google Maps/Places, OneSignal, and Twilio—our robust backend, built on cutting‑edge frameworks like React Native, ensures real‑time data capture, precise reporting, and effortless scalability to support a rapidly growing user base.

Post‑launch, FMHero benefits from a complimentary bug warranty and a maintenance window, along with comprehensive documentation covering every facet of development. This empowers FMHero’s team to manage and expand the platform independently—ensuring long‑term operational excellence and continuous innovation in HVAC/R compliance and service management.

Imagine a tool that transforms tedious paperwork into a streamlined, high‑tech workflow—empowering every technician to become a compliance hero. With FMHero, we’ve reimagined refrigerant management and service documentation, turning regulatory challenges into opportunities for efficiency and growth. Book your free 45‑minute consultation today, and let’s discuss how we can help you build a platform that not only meets industry standards but sets new ones.